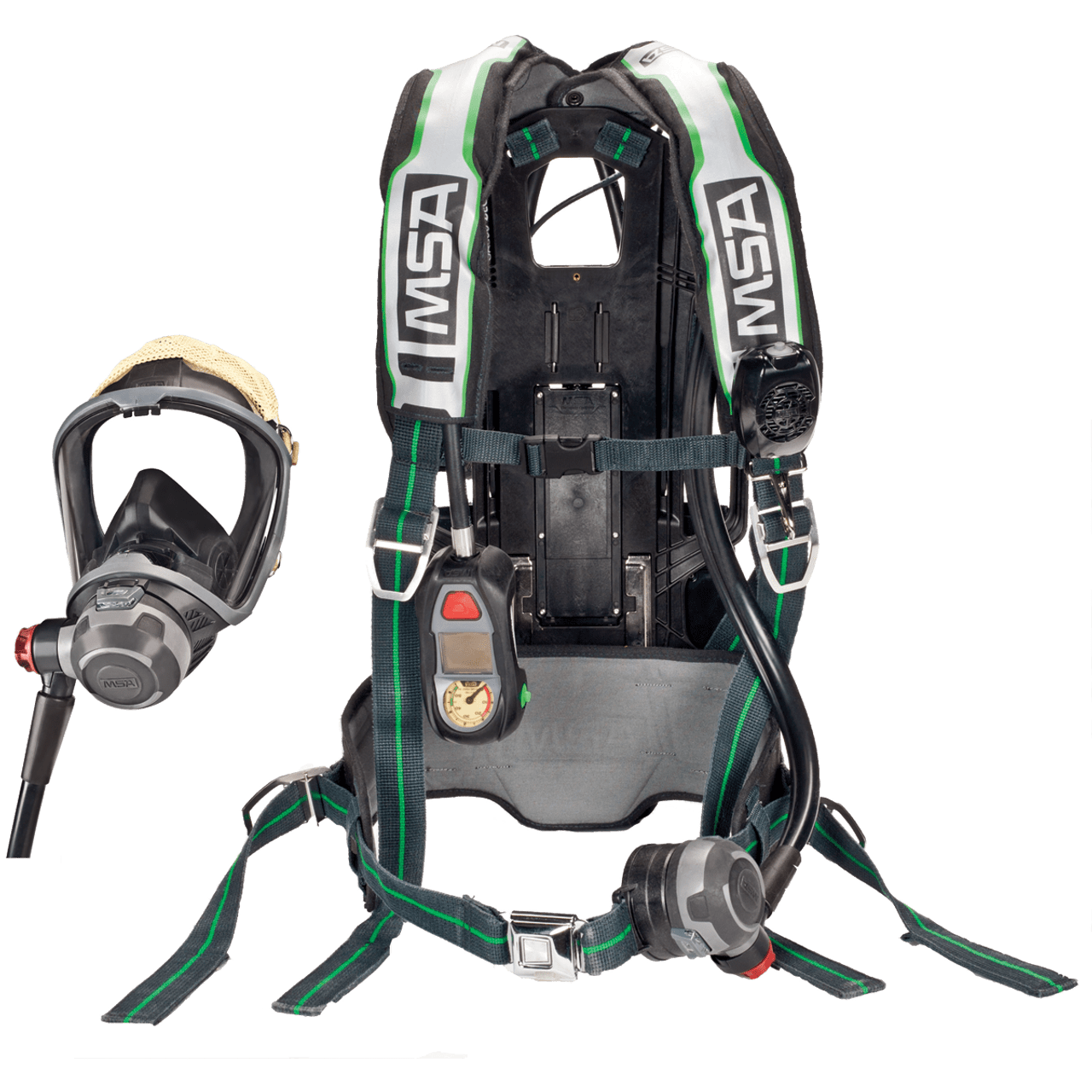

MSA G1 SCBA Parts Diagram: A Comprehensive Guide to Assembly, Maintenance, and Troubleshooting. This in-depth guide provides a detailed overview of the components, assembly, maintenance, and troubleshooting of MSA G1 SCBAs, ensuring optimal performance and safety.

The MSA G1 SCBA is a critical piece of safety equipment for firefighters and other first responders. Understanding its components and how to maintain and troubleshoot it is essential for ensuring its reliability and effectiveness in emergency situations.

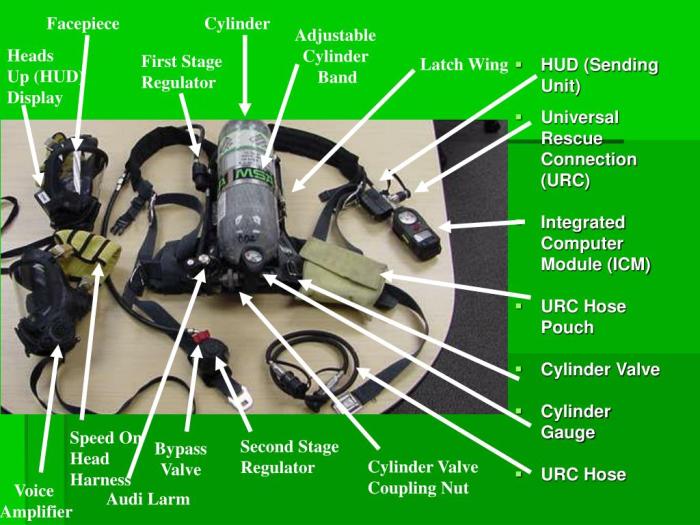

MSA G1 SCBA Parts Overview

The MSA G1 Self-Contained Breathing Apparatus (SCBA) system is a crucial safety device designed to provide breathable air to firefighters and other emergency responders in hazardous environments. It consists of several key components that work together to ensure the safety and functionality of the system.

The main components of an MSA G1 SCBA system can be organized into a hierarchical structure as follows:

- Main Assemblies:

- Backpack Assembly

- Facepiece Assembly

- Air Supply System

- Backpack Assembly:

- Harness

- Frame

- Cylinder

- Regulator

- Facepiece Assembly:

- Mask

- Head Harness

- Microphone

- Air Supply System:

- Cylinder

- Valve

- Pressure Gauge

Each of these components plays a vital role in the operation of the SCBA system. The backpack assembly houses the air supply and regulates the flow of breathable air to the user. The facepiece assembly provides a seal around the user’s face and delivers the air to the user’s lungs.

The air supply system stores and delivers the breathable air to the user.

MSA G1 SCBA Assembly and Disassembly

The MSA G1 SCBA is a self-contained breathing apparatus used by firefighters and other emergency responders. It is important to be able to properly assemble and disassemble the SCBA in order to ensure that it is functioning properly and is safe to use.

The following steps provide a general overview of the assembly and disassembly process for the MSA G1 SCBA:

Assembly

- Connect the regulator to the cylinder.The regulator is the device that controls the flow of air from the cylinder to the facepiece. To connect the regulator, first remove the protective cap from the cylinder valve. Then, screw the regulator onto the cylinder valve. Tighten the regulator until it is snug.

- Connect the hose to the regulator.The hose is the tube that carries air from the regulator to the facepiece. To connect the hose, first remove the protective cap from the regulator outlet. Then, push the hose onto the regulator outlet. Secure the hose with a hose clamp.

- Connect the facepiece to the hose.The facepiece is the part of the SCBA that covers the user’s face and provides them with air. To connect the facepiece, first remove the protective cap from the hose inlet. Then, push the facepiece onto the hose inlet. Secure the facepiece with a facepiece strap.

- Check the SCBA for leaks.Before using the SCBA, it is important to check it for leaks. To check for leaks, first turn on the air supply. Then, listen for any hissing sounds. If you hear any hissing sounds, it means that there is a leak in the SCBA.

Tighten the connections until the leak stops.

Disassembly

- Disconnect the facepiece from the hose.To disconnect the facepiece, first remove the facepiece strap. Then, pull the facepiece off of the hose inlet.

- Disconnect the hose from the regulator.To disconnect the hose, first remove the hose clamp. Then, pull the hose off of the regulator outlet.

- Disconnect the regulator from the cylinder.To disconnect the regulator, first turn off the air supply. Then, unscrew the regulator from the cylinder valve. Replace the protective cap on the cylinder valve.

MSA G1 SCBA Maintenance and Inspection

Regular maintenance and inspection are critical for the safe and reliable operation of MSA G1 SCBAs. Proper maintenance helps prevent failures, extends the life of the equipment, and ensures the SCBA is ready for use in an emergency.

The MSA G1 SCBA Maintenance and Inspection Guide provides detailed instructions for performing routine maintenance and inspections. It is important to follow the manufacturer’s recommendations and use only authorized parts and components.

Inspection Checklist

The following checklist provides a summary of the key inspection points for the MSA G1 SCBA:

| Inspection Point | Frequency | Action |

|---|---|---|

| Visual Inspection | Daily | Inspect for any damage, leaks, or corrosion. |

| Leak Testing | Monthly | Perform a leak test on the cylinder valve, regulator, and mask. |

| Functional Checks | Annually | Verify the operation of the pressure gauge, warning devices, and breathing circuit. |

MSA G1 SCBA Troubleshooting: Msa G1 Scba Parts Diagram

The MSA G1 SCBA is a reliable and durable piece of equipment, but like any other machine, it can occasionally experience problems. This section provides a guide to common problems that can occur with MSA G1 SCBAs and offers troubleshooting steps to help resolve them.

Before troubleshooting, it’s important to identify the symptoms of the problem. These symptoms can include:

- Difficulty breathing

- Airflow problems

- Pressure gauge readings that are out of range

- Leaks

- Electrical problems

Once the symptoms have been identified, the next step is to determine the potential causes of the problem. Some of the most common causes of MSA G1 SCBA problems include:

- Clogged filters

- Damaged hoses or valves

- Malfunctioning regulators

- Electrical shorts

- Battery problems

Once the potential causes of the problem have been identified, the next step is to take corrective action. The following are some general troubleshooting steps that can be followed:

- Check the air filter for clogs and replace it if necessary.

- Inspect the hoses and valves for damage and replace any that are damaged.

- Check the regulators for proper operation and adjust or replace them if necessary.

- Check the electrical connections for shorts and repair or replace any that are damaged.

- Check the battery for proper voltage and replace it if necessary.

If the problem persists after following the troubleshooting steps, it is recommended to contact a qualified technician for further assistance.

In addition to the general troubleshooting steps, there are also specific troubleshooting steps that can be taken for each of the common problems listed above.

Difficulty breathing

If you are experiencing difficulty breathing while using your MSA G1 SCBA, the first step is to check the air filter for clogs. If the air filter is clogged, it will restrict the flow of air to the regulator and make it difficult to breathe.

Replace the air filter if it is clogged.

If the air filter is not clogged, the next step is to check the hoses and valves for damage. If any of the hoses or valves are damaged, they will need to be replaced.

If you’re looking for a detailed diagram of MSA G1 SCBA parts, I recommend checking out this helpful resource. Alternatively, if you’re interested in testing your business simulation skills, I suggest you try the glo bus simulation quiz 1 . It’s a great way to practice making strategic decisions in a simulated business environment.

Returning to the MSA G1 SCBA parts diagram, remember to pay close attention to the various components and their functions.

If the hoses and valves are not damaged, the next step is to check the regulators for proper operation. The regulators are responsible for controlling the flow of air to the mask. If the regulators are not functioning properly, they will need to be adjusted or replaced.

Airflow problems

If you are experiencing airflow problems while using your MSA G1 SCBA, the first step is to check the air filter for clogs. If the air filter is clogged, it will restrict the flow of air to the regulator and make it difficult to breathe.

Replace the air filter if it is clogged.

If the air filter is not clogged, the next step is to check the hoses and valves for damage. If any of the hoses or valves are damaged, they will need to be replaced.

If the hoses and valves are not damaged, the next step is to check the regulators for proper operation. The regulators are responsible for controlling the flow of air to the mask. If the regulators are not functioning properly, they will need to be adjusted or replaced.

Pressure gauge readings that are out of range

If the pressure gauge readings on your MSA G1 SCBA are out of range, the first step is to check the air filter for clogs. If the air filter is clogged, it will restrict the flow of air to the regulator and cause the pressure gauge readings to be out of range.

Replace the air filter if it is clogged.

If the air filter is not clogged, the next step is to check the hoses and valves for damage. If any of the hoses or valves are damaged, they will need to be replaced.

If the hoses and valves are not damaged, the next step is to check the regulators for proper operation. The regulators are responsible for controlling the flow of air to the mask. If the regulators are not functioning properly, they will need to be adjusted or replaced.

Leaks, Msa g1 scba parts diagram

If you are experiencing leaks while using your MSA G1 SCBA, the first step is to check the hoses and valves for damage. If any of the hoses or valves are damaged, they will need to be replaced.

If the hoses and valves are not damaged, the next step is to check the regulators for proper operation. The regulators are responsible for controlling the flow of air to the mask. If the regulators are not functioning properly, they will need to be adjusted or replaced.

Electrical problems

If you are experiencing electrical problems while using your MSA G1 SCBA, the first step is to check the battery for proper voltage. If the battery voltage is low, the SCBA will not be able to function properly. Replace the battery if it is low.

If the battery voltage is not low, the next step is to check the electrical connections for shorts. If any of the electrical connections are shorted, they will need to be repaired or replaced.

MSA G1 SCBA Accessories and Upgrades

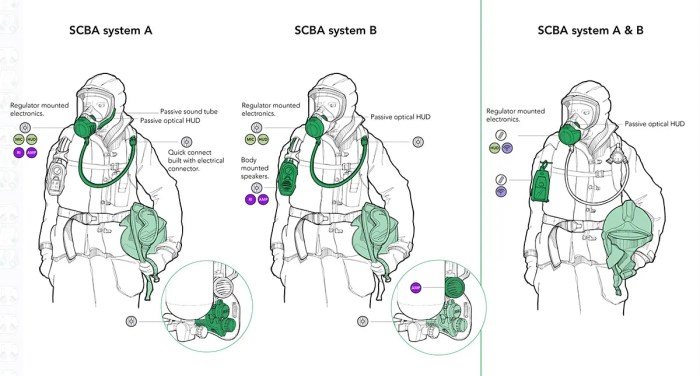

The MSA G1 SCBA offers a wide range of accessories and upgrades to enhance its functionality and versatility. These accessories are designed to meet the specific needs of different users and applications.

Communication Devices

*

-*MSA Sordin Supreme Pro X

This communication device provides clear and reliable voice communication in noisy environments. It features active noise reduction, adjustable volume levels, and compatibility with various radio systems.

-*MSA Aircom 3 Wireless Communication System

This wireless communication system allows users to communicate hands-free, even when wearing gloves or in confined spaces. It features full-duplex operation and automatic noise cancellation.

Lighting Systems

*

-*MSA GALAXY Headlamp

This headlamp provides bright and wide-angle illumination, freeing up the user’s hands for other tasks. It features multiple light modes, adjustable brightness, and a long runtime.

-*MSA SIRIUS Searchlight

This searchlight offers powerful and focused illumination for extended distances. It is ideal for search and rescue operations, hazmat incidents, and other low-light conditions.

Thermal Imaging Cameras

*

-*MSA Flir K55 Thermal Imaging Camera

This thermal imaging camera detects heat signatures, allowing users to see through smoke, darkness, and other obscurants. It is valuable for firefighting, search and rescue, and industrial inspections.

-*MSA Flir K65 Thermal Imaging Camera

This advanced thermal imaging camera offers higher resolution and sensitivity than the K55, providing even greater detail and clarity in challenging conditions.

Other Accessories

*

-*MSA Rescue Kit

This kit contains essential tools for confined space rescues, including a tripod, rescue harness, and rope.

-

-*MSA Escape Buddy System

This system provides a secondary air supply to a distressed user, allowing them to escape hazardous environments.

-*MSA Oxygen Cylinder

This cylinder provides additional oxygen supply for extended operations or emergencies.

-*MSA Carrying Case

This rugged case protects the SCBA and accessories during transport and storage.

These accessories enhance the MSA G1 SCBA’s capabilities, making it suitable for a wide range of applications and ensuring the safety and efficiency of users.

Clarifying Questions

What are the main components of an MSA G1 SCBA?

The main components of an MSA G1 SCBA include the facepiece, regulator, harness, cylinder, and alarm.

How often should an MSA G1 SCBA be inspected?

MSA G1 SCBAs should be inspected monthly, or more frequently if required by regulations or if the SCBA has been exposed to harsh conditions.

What are some common problems that can occur with MSA G1 SCBAs?

Some common problems that can occur with MSA G1 SCBAs include leaks, regulator malfunctions, and alarm failures.